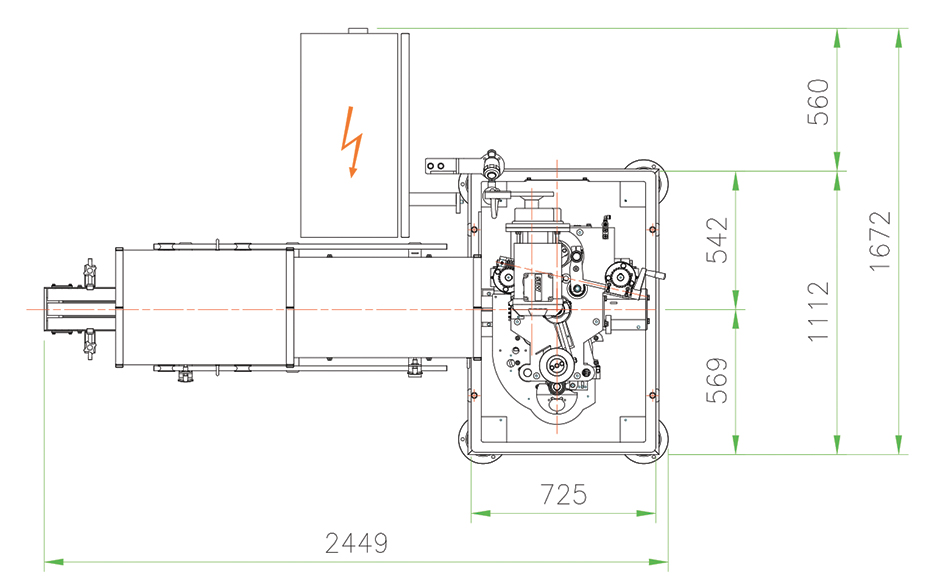

Rotating can seaming system.

The seamer B60L is a compact model specially designed for low capacity production.

The machine has the capacity of handling cans with diameters of 52mm to 99mm and heights of 24mm to 220mm.

The seamer consist of two monoblocks and an inlet conveyor with a worm to synchronize the cans.

- AISI 316 casting stainless steel base for greater stability

- The high-quality material protects against corrosive and aggressive products, such as sugar, salt, vinegar, etc.

- Cast iron with a nickel surface upper head

- Adjustable height of the head through a hand wheel

- Powered by 3 kW motor which has an inverter to regulate the production speed